In the realm of industrial sealing solutions, the Red Rubber O Ring has emerged as a vital component across various applications, from manufacturing to automotive industries. According to a recent industry report by the International Sealing Association, the demand for O Rings, particularly those made from red rubber, is projected to grow by 5% annually, underscoring their significance in maintaining fluid integrity and preventing leaks. Industry expert Dr. James Carver, a leading figure in materials engineering, notes, "Choosing the right O Ring material can significantly impact the efficiency and longevity of your systems." This statement highlights the critical importance of selecting the appropriate Red Rubber O Ring for effective project execution.

When embarking on projects that require meticulous attention to detail, understanding the nuances associated with Red Rubber O Rings becomes essential. Factors such as temperature resistance, compressibility, and chemical compatibility need to be carefully considered to ensure optimal performance. As industries evolve, the need for high-quality O Rings that can withstand rigorous operational demands is paramount. This article will delve into the top ten tips for choosing the perfect Red Rubber O Ring, equipping professionals with the knowledge necessary to make informed choices and enhance the reliability of their projects.

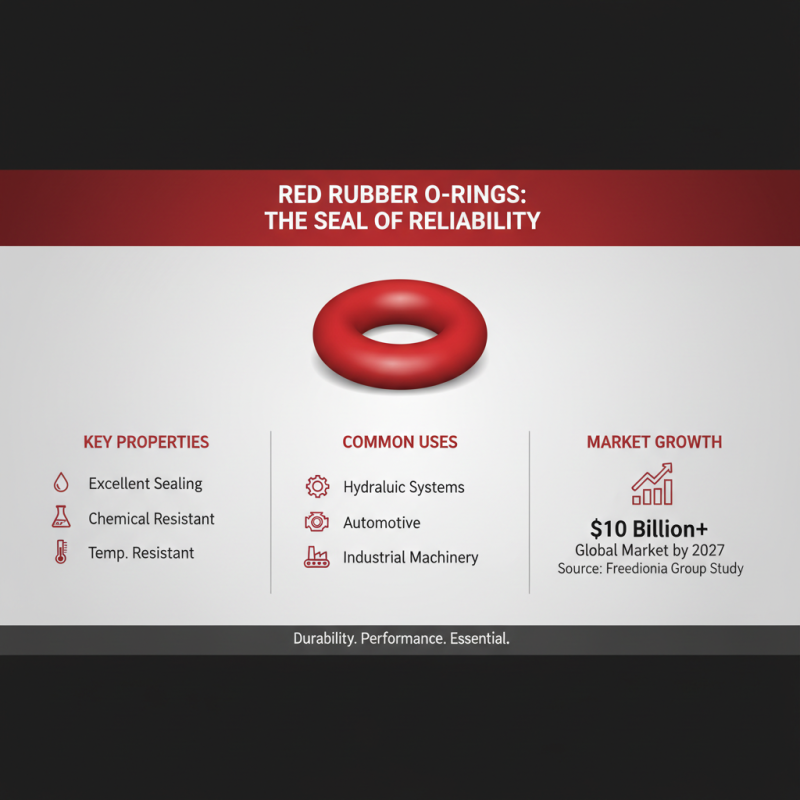

Red rubber O rings play a critical role in sealing applications across numerous industries, including automotive, aerospace, and industrial machinery. The unique properties of red rubber, primarily its resilience and flexibility, make it an ideal choice for environments requiring effective sealing solutions. Red rubber exhibits excellent resistance to water and various chemicals, enhancing its functionality in a wide range of sealing applications. According to the Hydraulics & Pneumatics magazine, seals are responsible for maintaining pressure and preventing leakage, with O rings being a top choice for their simplicity and reliability.

In terms of performance metrics, reports indicate that O rings can achieve sealing pressures up to 5,000 psi when properly sized and installed. The importance of material composition cannot be understated; red rubber O rings often utilize compounds that provide enhanced durability against abrasion and thermal degradation, crucial for high-temperature applications. A study conducted by the Institute of Rubber Products highlights that the right formulation can lead to a failure rate reduction of up to 30%, underscoring the necessity of selecting the appropriate type of O ring for specific operational conditions.

Understanding the environment in which these sealing components will function—including temperature fluctuations, pressure, and potential chemical exposure—is essential for achieving optimal performance. By carefully considering these factors, engineers and project managers can select red rubber O rings that not only fit the dimensional requirements but also withstand the rigors of their applications, thereby ensuring long-lasting seals that enhance operational efficiency.

| Tip Number | Tip Description | Material Properties | Application Areas |

|---|---|---|---|

| 1 | Determine the temperature range of your application. | Withstands temperatures from -40°F to 212°F. | Hydraulic systems, automotive applications. |

| 2 | Check compatibility with media being sealed. | Excellent resistance to water, oils, and some chemicals. | Industrial machinery, plumbing fixtures. |

| 3 | Select the right size for your application. | Precision cut to specific dimensions. | Electronics, home appliances. |

| 4 | Consider the durometer (hardness) rating. | Shore A hardness typically ranges from 40 to 90. | Food processing, medical devices. |

| 5 | Evaluate the chemical exposure for choosing materials. | Resistant to degradation from various fluids. | Chemical processing, automotive. |

| 6 | Account for installation and removal ease. | Flexible yet durable for easy handling. | Maintenance jobs, assembly lines. |

| 7 | Inspect for quality and certification marks. | Certified materials enhance trustworthiness. | Aerospace, defense. |

| 8 | Understand the working pressure rating. | Designed for specific pressure limits. | Fluid power systems, HVAC. |

| 9 | Choose between solid or split O-ring designs. | Solid for permanent seals; split for easy replacement. | Manufacturing, maintenance. |

| 10 | Consult manufacturer guidelines for installation. | Guidelines ensure optimal performance. | General engineering practices. |

When selecting the perfect red rubber O-ring for your projects, understanding the key material properties is essential. Red rubber, often made from neoprene or specialized synthetic compounds, exhibits impressive resilience and adaptability in a variety of applications. Its temperature resistance typically ranges from -40°F to 212°F (-40°C to 100°C), making it suitable for both high and low-temperature environments. According to industry reports, red rubber has a durometer hardness of 60 to 70 Shore A, which means it balances flexibility and strength effectively, providing reliable sealing capabilities under pressure.

Moreover, red rubber O-rings boast excellent resistance to water, many chemicals, and weathering, making them ideal for outdoor applications and environments with high humidity. The tensile strength of red rubber can reach up to 3,000 psi, which contributes to its durability in demanding conditions. Studies indicate that using the right rubber compound can significantly enhance the longevity of O-rings, reducing maintenance costs by up to 30% over time. When choosing the right O-ring, consider factors such as exposure to specific chemicals, temperature fluctuations, and the mechanical stresses involved in your project to ensure optimal performance and reliability.

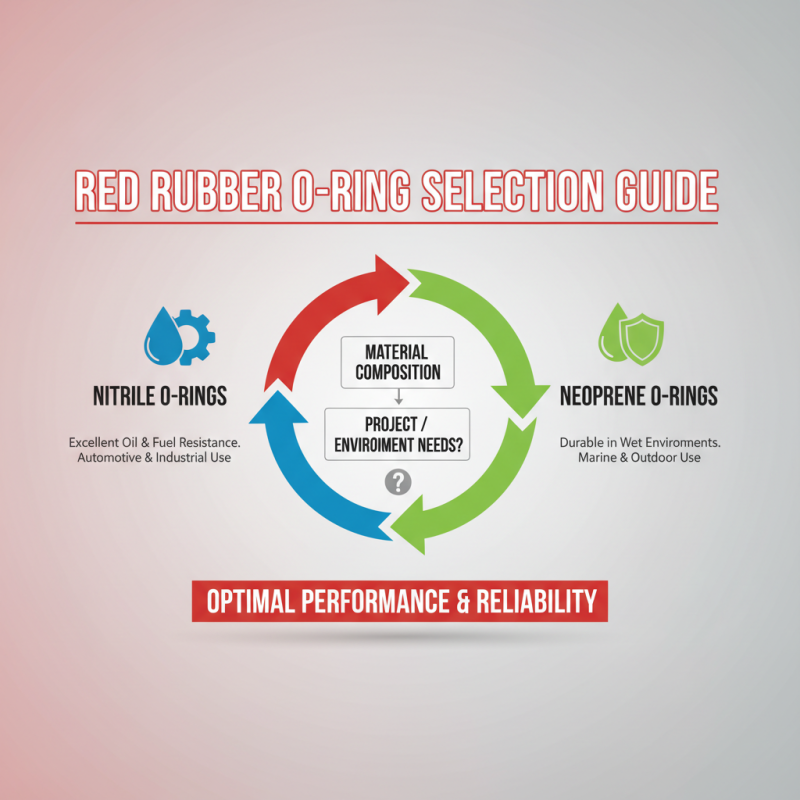

When selecting a red rubber O-ring for your projects, several critical factors must be considered to ensure optimal performance and reliability. One of the foremost aspects is the material composition. Red rubber O-rings are commonly made from a variety of elastomers, with the most popular being nitrile and neoprene. According to the Global O-Ring Market Report, nitrile O-rings provide excellent resistance to oils and fuels, making them suitable for automotive and industrial applications, while neoprene O-rings are known for their durability in wet environments. Understanding the specific environmental conditions your O-ring will face is essential for determining the right material.

Another vital factor is the O-ring's size and thickness. The effective sealing performance of an O-ring is heavily impacted by its dimensions. Data from the American Society for Testing and Materials (ASTM) suggests that improper sizing can lead to leaks or seal failure, highlighting the importance of accurately measuring the groove dimensions where the O-ring will be installed. Additionally, consider the temperature range the O-ring will encounter; both extreme heat and cold can alter the mechanical properties of the rubber. Ensuring that the selected O-ring operates well within the intended temperature range is crucial for maintaining its integrity over time. By closely evaluating material type, size, and operating conditions, you can select the perfect red rubber O-ring to meet your project needs.

When selecting the perfect red rubber O ring for your project, understanding the sizing guidelines is crucial to ensure optimal performance and longevity. The first step in sizing is to measure the inner diameter (ID) of the groove where the O ring will be seated. This measurement is critical because it directly influences how well the O ring will create a seal. Once the ID is established, the cross-sectional diameter, which determines the thickness of the O ring, must be considered. A thicker O ring can provide a stronger seal but may also create more friction, so balance is key depending on the application requirements.

Moreover, it's important to take into account the operational environment of the O ring. Factors such as temperature fluctuations, exposure to chemicals, and pressure levels can impact the size choice significantly. In applications where the O ring will be compressed, selecting a slightly larger ID can help accommodate the deformation without compromising the seal. Additionally, it's advisable to consult industry-specific charts or guidelines that provide recommendations for O ring sizes based on standard groove dimensions. By following these sizing guidelines, you can ensure that the red rubber O ring you choose will meet the demands of your specific project efficiently.

Red rubber O-rings are vital components used across various industries due to their excellent sealing properties and resistance to a wide range of chemicals and temperatures. These rings are commonly found in hydraulic systems, automotive applications, and machinery where they play a crucial role in preventing leaks and ensuring the reliability of operations. According to a study by Freedonia Group, the global O-ring market is expected to exceed $10 billion by 2027, with red rubber O-rings becoming increasingly popular due to their durability and performance characteristics.

In specific applications, red rubber O-rings are extensively utilized in plumbing and HVAC systems, where they effectively seal joints and prevent fluid from escaping. Their resistance to heat and wear makes them ideal for gaskets and seals in high-pressure conditions, such as those found in industrial machinery. Furthermore, the use of these O-rings in food processing and medical devices is on the rise, driven by stringent regulatory standards for hygiene and safety. The elastic nature of red rubber enables it to sustain pressure while maintaining a tight seal, which is a critical requirement in these sensitive environments. Industry reports suggest that the demand for such sealing solutions is projected to grow steadily as manufacturers increasingly prioritize reliability and efficiency in their designs.