Choosing the right Red Rubber O Ring can be daunting. Industry expert John Smith states, "Selecting the perfect O Ring is critical for performance." Each application has unique demands. The materials, size, and hardness all matter significantly.

Red Rubber O Rings serve various purposes. They seal fluids and prevent leaks in many devices. However, not all Red Rubber O Rings are created equal. Some might wear out quickly or fail under pressure. It's crucial to assess your specific needs.

Take the time to measure your requirements. Consider the temperature range and chemical compatibility. These factors influence the durability of the O Ring. A small oversight can lead to costly repairs or failures. Often, people overlook the importance of these details. Careful evaluation today can save headaches tomorrow.

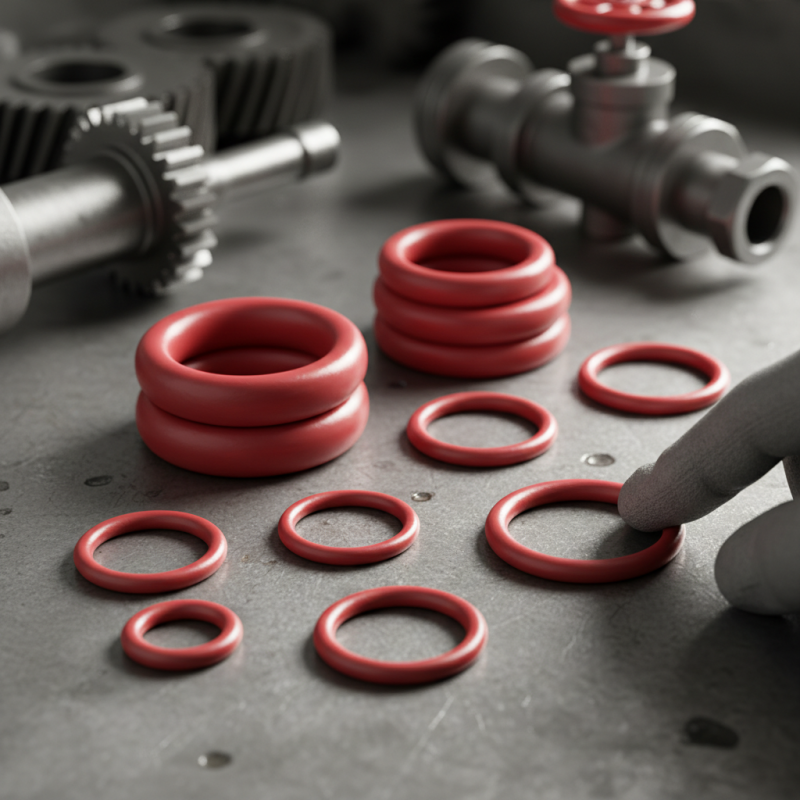

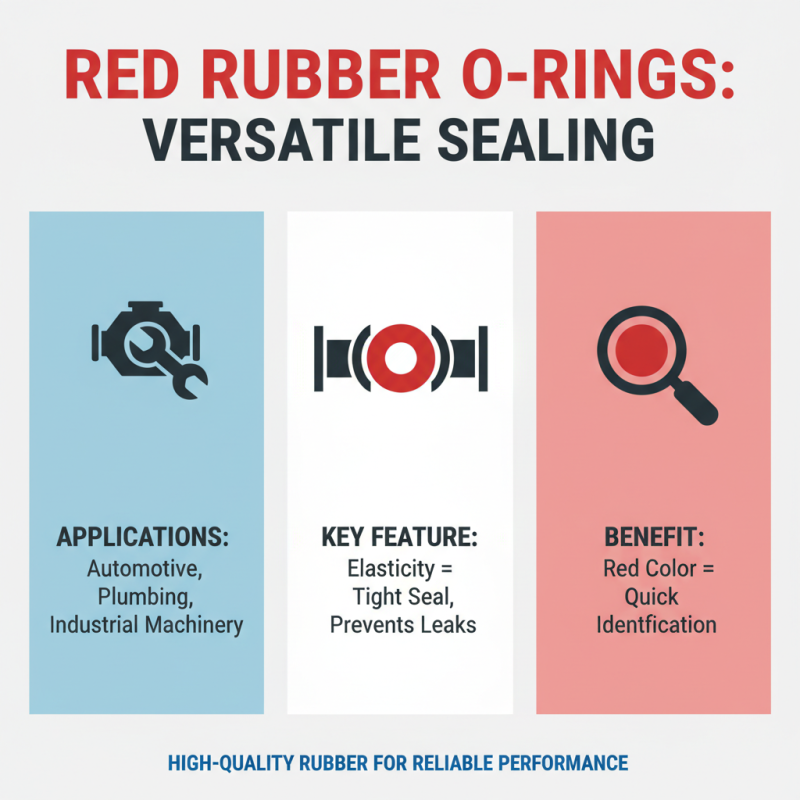

Red rubber O rings are versatile sealing solutions made from high-quality rubber. They are commonly used in various applications, including automotive, plumbing, and industrial machinery. Their elasticity allows them to create a tight seal, preventing leaks effectively. The red color also helps in identifying these O rings quickly during maintenance.

These O rings are particularly useful in environments with moderate temperatures and pressures. However, their performance may diminish in extreme conditions. Users often overlook the importance of temperature tolerance. A ring that is too soft may wear out faster. Conversely, one that is too rigid could crack under stress. It is essential to test and choose an O ring that matches specific requirements.

Moreover, while red rubber O rings are reliable, they may not suit all media types. For example, they can degrade when exposed to certain chemicals. Awareness of chemical compatibility is a common area where mistakes occur. Assessing the exact needs of your application can lead to better long-term performance and reliability. Conducting thorough research before making a selection is crucial for successful outcomes.

When selecting the right red rubber O-ring, several key factors come into play. It’s important to focus on the material. Red rubber often refers to a specific type of elastomer. It is essential for heat resistance. Ensure you select the right compound for your application. Consider the temperature range and any chemicals the O-ring will encounter.

Size is another crucial factor. Measure the inside diameter and cross-section accurately. A poor fit can lead to leaks or failures. Tips for measuring include using calipers. Double-check your measurements to confirm accuracy.

Compatibility with fluid types is vital as well. Not all red rubber O-rings perform equally in various environments. Some may swell or degrade. Think about the pressure and movement in the application. Sometimes, the right choice might feel unclear. Testing different options could be necessary. Be patient; it can take time to find the perfect fit.

When selecting a red rubber O ring, understanding the various types is crucial. The most common types are Buna-N and silicone. Buna-N offers excellent resistance to oils and fuels. It is known for its durability in many applications. Silicone O rings, on the other hand, excel in high-temperature conditions. They provide good elasticity, but may not withstand certain oils.

Different features come with these O rings. For example, the hardness rating, measured in durometers, affects performance. Softer O rings can create better seals, while harder ones resist wear better. Color is often not just aesthetic; it can indicate material type. Red typically signifies synthetic rubber, which can withstand harsh conditions better than natural rubber.

It's also essential to consider the size. An improperly sized O ring can lead to leaks or failures. Measuring accurately is key. Many users overlook the importance of compatibility with their fluids. If in doubt, consulting with a specialist can save time and avoid mistakes. The choice may seem simple, but each type has nuances that deserve attention.

When selecting a red rubber O-ring, consider its compatibility with chemicals. Some rubber materials can degrade when exposed to specific solvents or corrosive substances. This can lead to seal failure and costly repairs. Always check chemical compatibility charts before making a choice.

Tips: Research the chemical properties involved. Review the temperature and pressure ranges, too. Understand that not all red rubber O-rings are created equal in this aspect.

Environmental conditions also matter. Factors like humidity, temperature extremes, and exposure to UV light can affect performance. For instance, high temperatures may cause rubber to lose its shape. It’s crucial to evaluate the operating environment thoroughly.

Tips: Test your selected O-ring in real conditions when possible. Monitor its performance over time. Doing so can reveal hidden weaknesses and prevent future issues.

| O Ring Size (ID x CS) | Material Type | Temperature Range (°C) | Chemical Compatibility | Environmental Resistance |

|---|---|---|---|---|

| 10mm x 2mm | Nitrile (NBR) | -30 to 100 | Oil, Fuel | Moderate |

| 15mm x 3mm | Silicone | -50 to 200 | Water, Ozone | High |

| 20mm x 4mm | Fluoroelastomer (FKM) | -20 to 200 | Hydrocarbons, Chemicals | Very High |

| 25mm x 5mm | Polyurethane | -30 to 80 | Aging Oil, Solvents | Moderate |

When it comes to O rings, proper installation and maintenance are critical. According to industry reports, improper installation can lead to failure rates as high as 30%. Ensuring the correct size and fit is essential. Before installation, inspect the O ring for any visible flaws. Even minor imperfections can cause leaks.

Clean the groove and surrounding area thoroughly. Dust and debris can compromise the seal. Use a suitable lubricant to ease installation, but avoid over-lubrication. Excessive lubricant can create a slippage issue. Industry data shows that O rings installed with proper lubrication last 25% longer.

Regular maintenance is crucial for optimal performance. Monitor for signs of wear, like discoloration or brittleness. It's advisable to replace O rings every few months, especially in high-demand applications. While it may seem repetitive, many forget this step, leading to costly replacements later. Make routine checks a priority; it’s a small effort that pays off significantly.