In the rapidly evolving landscape of manufacturing and engineering, the selection of components such as Tiny O Rings has become a focal point for designers and engineers aiming for efficiency and reliability in their projects. According to a recent report by the International Rubber Research and Development Board, the demand for precision sealing solutions like Tiny O Rings is projected to grow significantly, highlighting their importance in various applications across multiple industries. These small yet crucial components are instrumental in preventing leaks, reducing friction, and ensuring the longevity of mechanical systems.

Experts in the field, such as Dr. James Hargrove, a leading authority on elastomeric materials, emphasize the critical nature of choosing the right Tiny O Rings for specific applications. Dr. Hargrove states, "The effectiveness of a sealing solution directly impacts the performance and lifespan of machinery. Selecting the appropriate Tiny O Rings can lead to remarkable improvements in efficiency and safety." As professionals navigate the intricate selection process, understanding material properties, sizing, and environmental compatibility becomes essential. The following guide will provide insights and criteria to aid in making informed decisions regarding Tiny O Rings for various projects, reflecting on industry standards and expert recommendations.

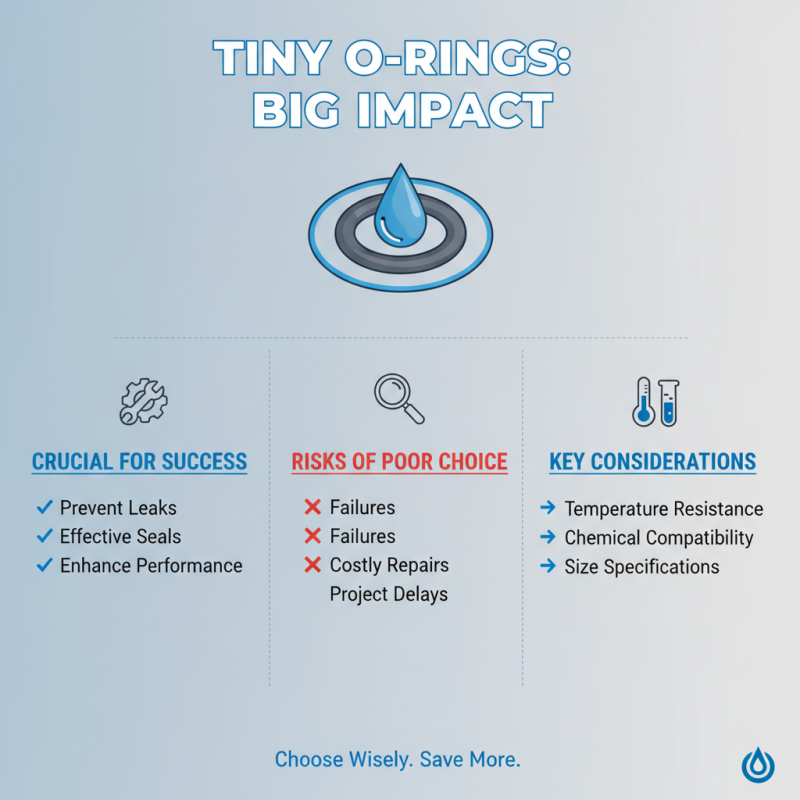

Selecting the right tiny O rings is crucial for ensuring the success of your projects. Tiny O rings may seem like small components, but their role in creating effective seals and preventing leaks cannot be underestimated. A well-chosen O ring can enhance the performance and longevity of your assembly, while a poor choice can lead to failures, costly repairs, and project delays. Understanding the specific requirements of your application, such as temperature resistance, chemical compatibility, and size specifications, is essential when making your selection.

Tips for choosing the best tiny O rings include meticulously assessing the operating environment in which they will be used. Consider factors like pressure fluctuations and exposure to various substances. Additionally, always refer to standardized sizing guides to ensure your O rings fit correctly in their designated grooves. Quality materials are also important; look for O rings made from durable elastomers that can withstand the stress and strain of your projects without degrading.

Another useful tip is to perform a test installation when possible. This helps you identify any potential issues with fit and functionality before committing to larger quantities. If your project involves frequent assembly and disassembly, selecting O rings designed for easy replacement can save time and improve efficiency. Remember, the right tiny O rings not only improve reliability but also contribute to the overall success of your projects.

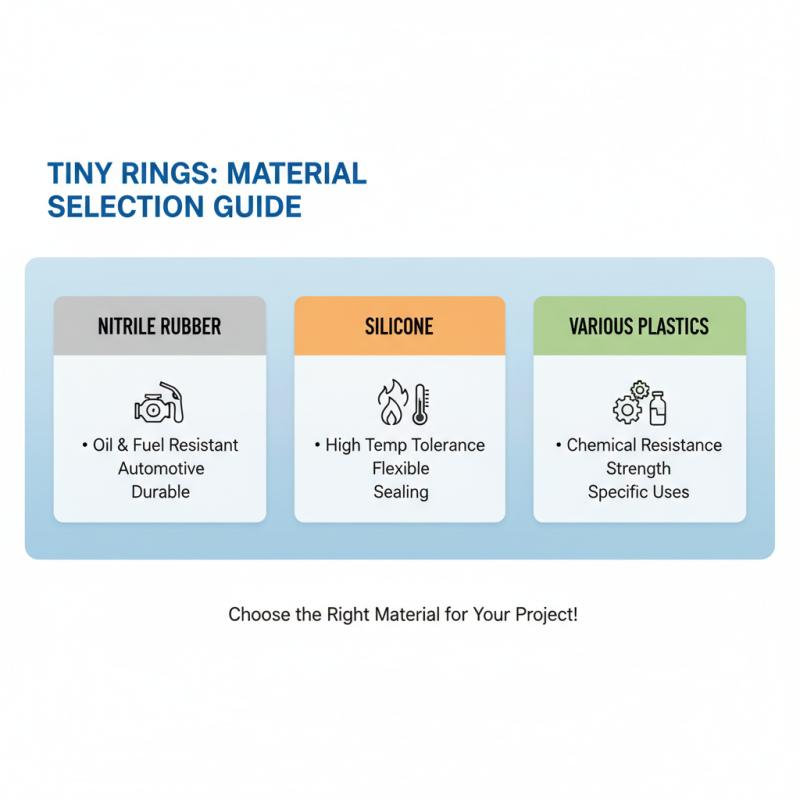

When selecting tiny O rings for your projects, understanding the key materials used and their performance characteristics is paramount. Common materials include rubber, silicone, and various plastics, each exhibiting unique properties that affect their suitability for different applications. For example, nitrile rubber is known for its excellent resistance to oils and fuels, making it a preferred choice for automotive applications. Silicone, on the other hand, offers a remarkable temperature tolerance and flexibility, which is ideal for sealing in high-heat environments.

In addition to rubber and silicone, you may also encounter O rings made from materials like fluorocarbon and polyurethane. Fluorocarbon O rings exhibit exceptional chemical resistance, making them highly suitable for harsh environments where exposure to corrosive substances is a concern. Polyurethane O rings are prized for their durability and tear resistance, proving effective in applications requiring a long service life. When choosing the right tiny O ring for your project, consider the operating conditions, including temperature fluctuations, exposure to chemicals, and the mechanical requirements of your system to ensure optimal performance and longevity.

When selecting tiny O rings for various applications, it is crucial to understand the industry standards and specifications that govern their design and use. Tiny O rings, often made from elastomeric materials, are utilized in a myriad of projects ranging from automotive to electronics, and even in household items. These components must meet particular criteria related to their diameter, thickness, and material resilience to ensure they perform effectively under specific environments, such as varying temperatures, pressures, and exposure to chemicals.

Industry standards, such as those set by the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO), provide guidelines for the dimensions and tolerances of O rings. For instance, clarity regarding the durometer hardness, which indicates the material's hardness, is essential for determining how well an O ring will seal against fluids or gases. Additionally, specifications related to the compatibility of materials with different substances can greatly influence the lifespan and reliability of the O rings in application. By adhering to these standards, manufacturers can ensure that their tiny O rings not only fit well but also perform consistently across various operating conditions, thus avoiding common pitfalls such as leaks or premature wear.

| O Ring Size (ID x OD x Width) | Material | Temperature Range (°C) | Pressure Rating (PSI) | Common Applications |

|---|---|---|---|---|

| 2.5mm x 5mm x 1mm | Nitrile (NBR) | -40 to 100 | 150 | Automotive, Industrial Machinery |

| 3mm x 6mm x 1.5mm | Fluoroelastomer (FKM) | -20 to 200 | 300 | Chemical Processing, Aerospace |

| 4mm x 8mm x 2mm | Silicone | -60 to 230 | 50 | Medical Devices, Food Industry |

| 5mm x 10mm x 2mm | EPDM | -40 to 120 | 200 | Water Systems, HVAC |

| 2mm x 4mm x 1mm | Polyurethane | -30 to 80 | 100 | Sealing, Automotive |

Tiny O rings, though small in size, play an essential role across various industries. They are widely used in applications ranging from automotive to aerospace, plumbing to electronics. These seals are primarily employed to prevent leaks, secure connections, and provide cushioning. In the automotive industry, for example, tiny O rings are used in fuel systems and engine components to maintain pressure and prevent the escape of fluids. Meanwhile, in the aerospace sector, they are critical for ensuring the integrity of hydraulic systems.

When considering the best tiny O rings for your projects, it is crucial to understand their material composition, as this directly affects their performance. Different materials such as silicone, neoprene, and fluorocarbon have unique properties tailored to specific applications.

Tips: Before selecting O rings, always assess the operating temperature and chemical exposure of your project. Additionally, check for standard sizes and certifications which may simplify compliance and installation in more regulated industries. Understanding these elements can significantly enhance the performance and durability of your applications, ensuring that your project runs smoothly and efficiently.

When sourcing quality tiny O rings for your projects, the importance of reliable suppliers cannot be overstated. According to a recent industry report from the International Rubber Study Group, the demand for elastomer components, including O rings, is projected to grow by approximately 5% annually through 2025. This rising demand emphasizes the need for sourcing from suppliers who adhere to stringent quality standards to ensure product performance, longevity, and safety.

To find dependable suppliers, it's crucial to assess their certification and compliance with industry standards such as ISO 9001. Suppliers who have standardized processes are often more likely to provide consistent quality in their O rings. Additionally, examining customer reviews and seeking recommendations from industry peers can provide insights into supplier reliability. A survey conducted by the Association for Rubber Products Manufacturers highlighted that around 40% of manufacturers consider supplier performance and reliability as critical factors in their sourcing decisions. Hence, establishing a relationship with reputable suppliers can help mitigate risks and improve the success rate of your projects.