Choosing the right Molded Rubber Components is crucial for various industries. These components play a vital role in manufacturing, automotive, and aerospace applications. According to a recent market report by Smith & Associates, the demand for molded rubber parts is projected to grow by 5% annually over the next five years.

Expert John Roberts, a leading figure in the molded rubber industry, emphasizes, “Selecting the right molded components can significantly enhance product performance.” However, this process can be difficult. Many projects fail due to improper material selection or inadequate customizations.

Understanding your project requirements is key. Factors include temperature resistance, chemical exposure, and mechanical durability. Sometimes, even minor mistakes in selecting molded rubber parts can lead to major project setbacks. Thus, it's essential to reflect on your choices and consider expert advice.

Molded rubber components are essential in various industries. They serve different purposes, such as seals, gaskets, and vibration dampeners. Understanding their basics helps in making better choices for your project. Molded rubber is flexible and resilient, which provides advantages in numerous applications. These qualities also make it a challenging material to work with.

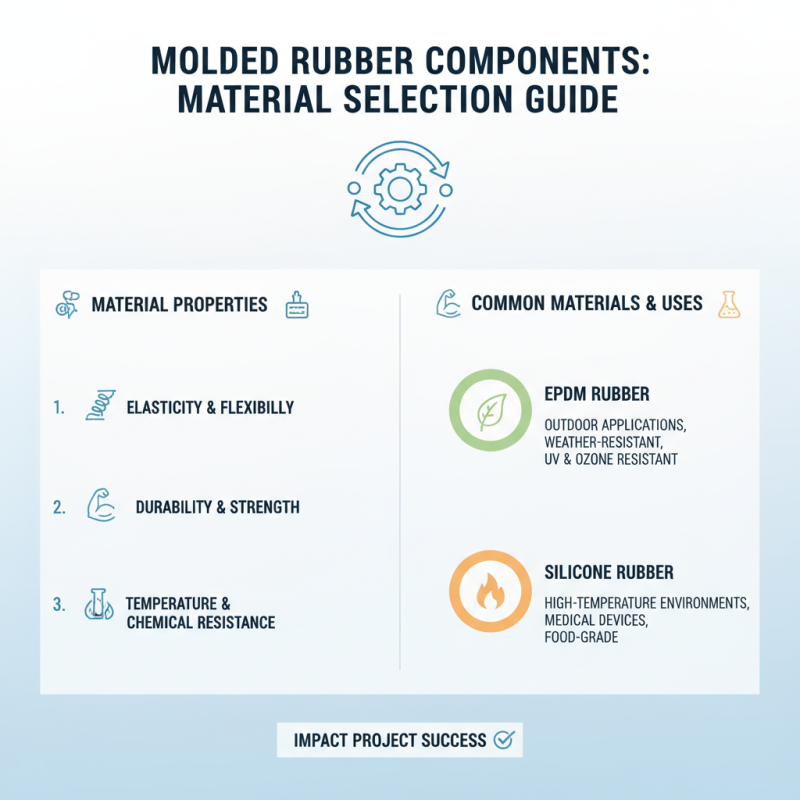

When selecting molded rubber components, consider the material properties. Hardness, temperature resistance, and chemical compatibility vary. Some components may fail under specific conditions. Testing them in your environment can reveal weaknesses. Pay attention to surface finishes and dimensions, as these factors impact fit and performance. Sizing errors can lead to significant project delays.

Molded rubber can also have imperfections. Air bubbles and inconsistent density are not uncommon. These issues may impact functionality. Regular quality inspections are crucial. Engaging with manufacturers who prioritize quality can mitigate risks. Ultimately, understanding the intricacies of molded rubber is vital for a successful project outcome. Choosing the right components requires both knowledge and careful evaluation.

Choosing the right molded rubber components can significantly impact your project's success. One critical factor is the type of rubber material used. Different compounds offer unique properties. For instance, EPDM is excellent for outdoor applications due to its weather resistance. Meanwhile, silicone rubber works well in high-temperature environments.

Durability is another aspect to consider. A component must withstand mechanical stress and environmental factors. Some rubbers degrade over time. It’s essential to analyze the specific conditions your project will face. Additionally, pay attention to the hardness of the rubber. Shore hardness affects flexibility and resilience. Be mindful of these nuances as they can make or break your project’s performance.

Finally, don’t overlook the manufacturing process. Different techniques, such as compression or injection molding, lead to varying results. Each method has its advantages and limitations. Experimentation might be necessary to find the perfect fit. These factors require careful consideration and reflection. Making a hasty choice can lead to failures that set back timelines. Ensure you weigh all options before decisively moving forward.

When selecting molded rubber components, design requirements are crucial. Understanding your project's needs can greatly influence the outcome. Factors like flexibility, hardness, and chemical resistance should guide your choices. Research shows that 65% of engineers prioritize material performance when assessing rubber parts.

Consider how these characteristics fit your application. For example, a high-durometer rubber might offer excellent durability but could lack the flexibility needed in certain settings. Evaluating your specific conditions is essential. A report from the Rubber Manufacturers Association indicates that over 30% of projects suffer due to misalignment between material properties and application demands.

Additionally, think about the environment where the component will be used. Exposure to heat, UV light, or chemicals can affect performance. According to industry studies, 40% of failures in rubber parts are linked to inadequate environmental assessments. It’s vital to reflect on these factors to avoid potential pitfalls in your project.

| Dimension | Material Type | Shore Hardness | Color Options | Application Area |

|---|---|---|---|---|

| 25mm x 15mm | Natural Rubber | 60A | Black, Red | Automotive Seals |

| 50mm x 30mm | Silicone Rubber | 70A | Clear, Blue | Medical Devices |

| 30mm x 10mm | EPDM Rubber | 50A | Black | Weather Seals |

| 40mm x 20mm | Nitrile Rubber | 80A | Black | Oil Seals |

| 20mm x 5mm | Neoprene Rubber | 60A | Black | Flexible Joints |

When selecting molded rubber components for various projects, assessing manufacturer capabilities is crucial. A recent industry report found that 70% of project failures stem from material quality issues. It emphasizes the importance of choosing manufacturers with robust quality standards. A manufacturer’s certifications can reveal their commitment to excellence. Look for ISO certifications, which indicate adherence to recognized standards.

Not all manufacturers implement strict quality control measures. Some may cut corners to reduce costs. This can lead to inconsistent product quality. Nearly 30% of companies reported issues with parts that did not meet specifications. Engaging with manufacturers to understand their processes can provide insights into their operational integrity. Ask about testing methods and material sourcing. This information can inform better decision-making.

Moreover, build a relationship with suppliers. Trust can be an essential factor in manufacturing reliability. In a competitive market, responsive and transparent communication is vital. Keep in mind that location matters too. Proximity to manufacturers can affect lead times and logistics, which are critical for timely project completion. Prioritize suppliers who show a willingness to collaborate, adapting to your unique project requirements.

Molded rubber components are versatile and widely used in various industries. They find common applications in automotive, aerospace, and consumer goods. For instance, in automotive manufacturing, rubber seals and gaskets are crucial. They prevent leaks and enhance performance. In aerospace, rubber components help maintain safety and efficiency. They are often used in engine mounts and vibration dampeners.

In consumer products, molded rubber parts enhance durability. Think of phone cases or kitchen utensils. These items need to withstand daily wear and tear. However, choosing the right rubber type is essential. Factors like temperature resistance and flexibility matter. Not all molded rubber is created equal. Some may not perform well under specific conditions. Testing is vital.

It’s also important to consider the intended use. Will the component be exposed to sunlight? Or will it face harsh chemicals? Each application has different requirements. Reflection on these aspects can lead to better decisions. Sometimes, a trial-and-error approach may be necessary. But careful consideration often leads to successful projects.