Selecting the right Molded Gaskets for your applications can be challenging. The gasket industry has experienced significant growth, with the global market projected to reach $7.5 billion by 2025. Molded Gaskets play a crucial role in a variety of sectors, including automotive, aerospace, and manufacturing. Their ability to provide excellent sealing under high pressures and temperatures makes them indispensable.

In recent years, high-performance materials have emerged, allowing Molded Gaskets to enhance durability. However, not every gasket suits every application. Many engineers encounter issues when selecting the right thickness, material, or design. Data suggests that 30% of gasket failures stem from improper selection, leading to costly downtime. This highlights the need for careful evaluation and testing in real-world conditions.

Choosing Molded Gaskets requires more than just understanding specifications. Factors such as environmental conditions, chemical exposure, and application requirements must be considered. Missteps in this process can result in significant inefficiencies. Before making a choice, it's essential to reflect on both current needs and potential future developments. Being informed ensures optimal performance and longevity in your applications.

Molded gaskets play a crucial role in various industries, ensuring a tight seal in numerous applications. Different types of molded gaskets are available, and understanding these can significantly impact selection. Common options include rubber gaskets, silicone gaskets, and plastic gaskets. Each type varies in durability, temperature resistance, and chemical compatibility. For example, silicone gaskets often withstand extreme temperatures, making them ideal for automotive applications.

Industry data indicates that the global gasket market is projected to grow significantly, with a CAGR of over 3.5% from 2021 to 2026. This growth reflects a rising demand for high-performance sealing solutions. However, it’s essential to choose gaskets based on specific application requirements rather than general characteristics. Some users have reported premature failures due to using inappropriate materials. Always consider the environment where the gasket will be used. Ensure it matches the necessary pressure, temperature, and chemical exposure levels.

Material selection can be tricky. Many overlook how compression set and overall resilience affect performance. For instance, a gasket may fail if it cannot maintain its shape under pressure. This failure can lead to costly leaks or equipment damage. Users need to invest time in evaluating each option's specifications. Performance tests and material certifications can provide valuable insights. Making informed decisions can largely affect outcomes in practical applications.

Choosing the right molded gaskets requires a deep understanding of material compatibility. Each application has unique demands. That's where assessing material compatibility becomes crucial. Certain materials excel in high temperatures, while others resist corrosion. However, not all materials work well together. This misalignment can lead to leaks or system failures.

Consider a scenario where rubber gaskets are used in chemical processing. If the chosen rubber does not withstand specific chemicals, it may degrade quickly. This can result in costly downtime. Engineers must examine the chemical composition of both the gasket material and the substances it will encounter. Testing for compatibility is essential but often overlooked.

Moreover, environmental factors play a significant role too. Humidity, temperature fluctuations, and exposure to UV light can affect gasket performance. Selecting a material based solely on its initial resistance can lead to issues later. It’s worth asking: does the gasket material maintain integrity under varying conditions? The answers aren't always clear-cut, highlighting the importance of thorough research and testing in gasket selection.

Choosing the right molded gaskets involves understanding performance criteria and industry standards. Key performance indicators include compressive strength, sealing ability, and temperature resistance. Gaskets must endure specific pressures and temperatures while maintaining integrity.

According to industry reports, over 70% of gasket failures arise from improper material selection. This statistic emphasizes the importance of evaluating materials. For instance, elastomers generally excel in flexibility but may falter in high-heat applications. Conversely, materials like PTFE offer excellent chemical resistance but might lack the required compressive strength.

Testing standards such as ASTM and ISO provide essential benchmarks. These standards guide manufacturers in assessing the lifespan and reliability of their gaskets. A newly released study indicated that gaskets meeting these standards exhibit a 30% lower failure rate. Considering these performance aspects is crucial when selecting molded gaskets. Be mindful of mismatches in application requirements and materials. Reflecting on these criteria can lead to better gasket performance and prolonged equipment life.

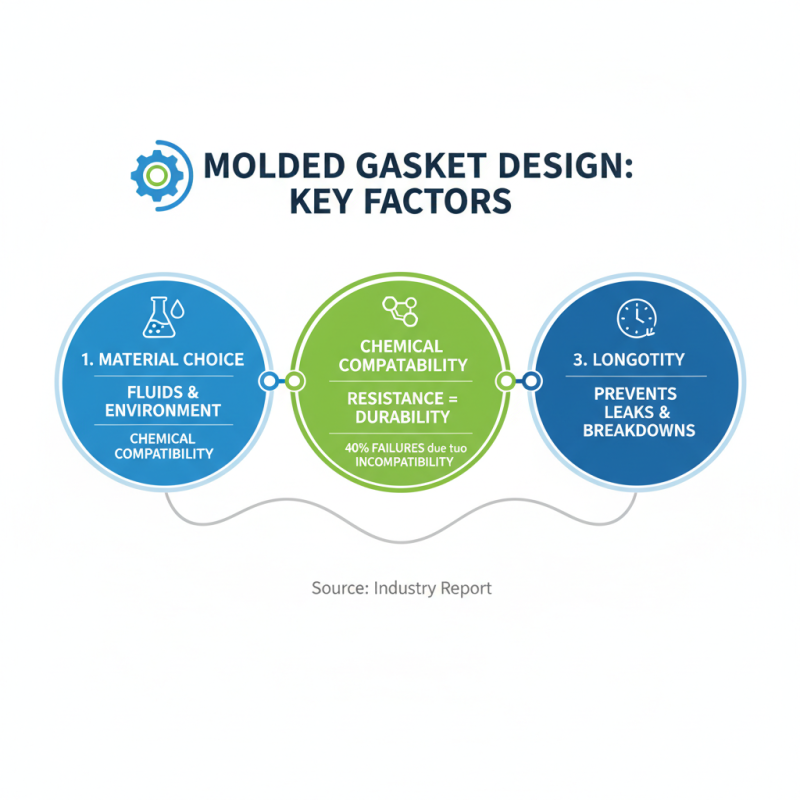

When designing molded gaskets, several factors are crucial. The material choice is vital for ensuring compatibility with fluids and environmental conditions. For example, according to a recent industry report, approximately 40% of gasket failures are due to chemical incompatibility. Selecting a material that resists the specific chemicals in use is essential for durability.

Another consideration is the gasket's configuration. The design must accommodate various surface finishes and load conditions. A study highlighted that improper configuration contributes to nearly 30% of leakage issues. Careful calculation of compression and stress distribution can prevent many common problems. Understanding whether a flat or conformable gasket profile is appropriate for your application can save time and costs.

Finally, the installation process is often overlooked. While it seems straightforward, improper installation can lead to premature failures. 20% of cases analyzed in a recent survey pointed to installation errors as the main cause of gasket performance issues. Training personnel in proper installation techniques can mitigate these risks significantly. Adopting a systematic approach and focusing on these areas can greatly enhance gasket efficiency.

Installing molded gaskets requires careful attention to detail. Ensure the surfaces are clean and free of debris. Dirt or old gasket material can lead to leaks over time. Use a dedicated cleaner to prepare the surfaces. This might seem tedious, but it is essential.

Torque specifications are vital during installation. Over-tightening can deform the gasket, while under-tightening can cause seal failure. Follow guidelines closely, checking the torque of bolts after initial installation. It’s easy to overlook, yet it can significantly affect performance.

Regular maintenance is crucial for longevity. Inspect molded gaskets periodically for signs of wear or damage. Look for cracks or compression set, which can indicate issues. Keeping track of how these gaskets perform can highlight potential problems early. Small vigilance can prevent larger issues down the line.