Choosing the right Propane Tank Rubber Gasket is a crucial step in ensuring the safety and efficiency of your propane system. Whether you're using propane for heating, cooking, or powering equipment, the integrity of your gasket can significantly impact performance and leak prevention. A high-quality rubber gasket provides a reliable seal, preventing gas leakage and potential hazards, while also enhancing the longevity of your propane setup.

In this guide, we will explore essential factors to consider when selecting the appropriate Propane Tank Rubber Gasket for your specific needs. You'll learn about the different materials available, their respective properties, and how they influence the performance of the gasket. Additionally, we'll cover the importance of compatibility with your propane tank and any environmental factors that could affect gasket functionality. By the end of this article, you will be well-equipped to make an informed decision that ensures safety and reliability in your propane applications.

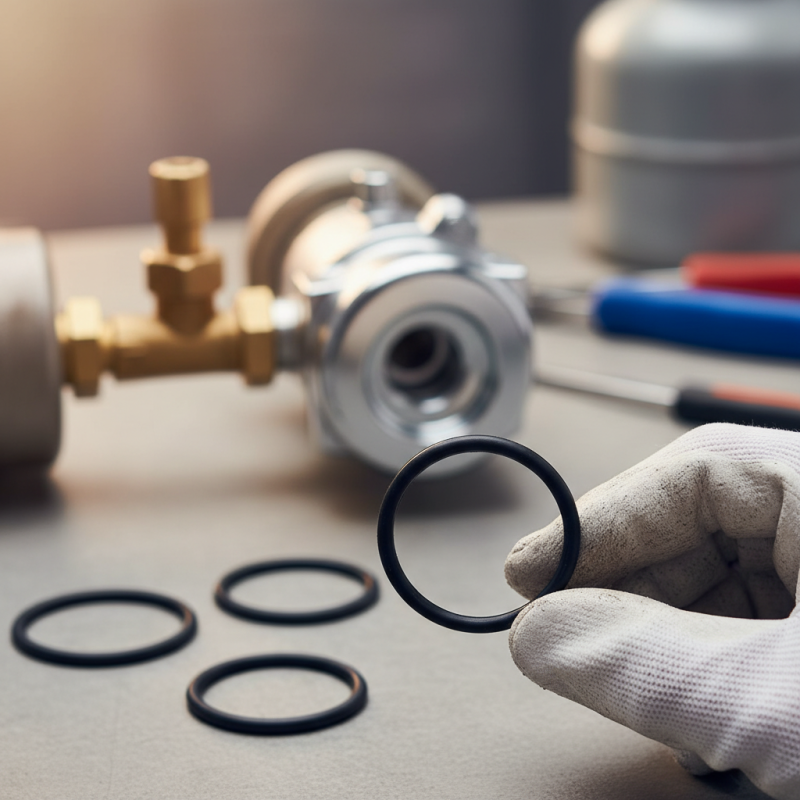

Understanding the functionality of propane tank rubber gaskets is crucial for ensuring safety and efficiency in propane storage and usage. These gaskets serve as seals around the valve and filling points of propane tanks, preventing leaks that could lead to dangerous situations. Made from durable rubber materials, they are designed to withstand temperature fluctuations and exposure to propane, contributing to the overall integrity of the tank. A properly fitted gasket maintains the pressure within the tank while also protecting the contents from external contaminants.

In addition to their sealing function, rubber gaskets play a vital role in the maintenance of propane systems. They provide a barrier that helps to prevent corrosion caused by gas exposure, thereby extending the lifespan of the tank and its components. When selecting a rubber gasket, it is essential to consider factors such as compatibility with propane, temperature ratings, and the specific dimensions of the tank. Understanding these aspects will help users choose the right gasket that not only ensures safety but also enhances the performance of their propane systems.

When selecting the right rubber gasket for your propane tank, understanding the different types available and their unique characteristics is crucial. Rubber gaskets typically come in various materials, including neoprene, EPDM (ethylene propylene diene monomer), and Nitrile. Neoprene is known for its excellent weather resistance and durability, making it a popular choice for outdoor applications. EPDM, on the other hand, offers outstanding resistance to heat, aging, and ozone, making it suitable for environments with extreme temperatures. Nitrile rubber gaskets provide good oil resistance, making them ideal for applications where exposure to fuels or oily substances may occur.

Additionally, the size and shape of the gasket are vital factors in ensuring a proper seal. Gaskets are available in numerous configurations, such as flat, round, or custom shapes, allowing for tailored solutions based on the specific design of your propane tank. The thickness of the gasket also plays a significant role in its effectiveness; a thicker gasket may provide a better seal but can also influence the overall fit. It's essential to assess both the physical and chemical requirements of your application to select the right gasket material and configuration that meets your operational needs and ensures the safety and performance of your propane tank system.

| Type of Gasket | Material | Temperature Resistance (°F) | Pressure Rating (psi) | Best Use Case |

|---|---|---|---|---|

| EPDM Gasket | Ethylene Propylene Diene Monomer | -40 to 230 | 150 | Residential Propane Tanks |

| Nitrile Gasket | Nitrile Butadiene Rubber | -30 to 212 | 200 | Industrial Propane Applications |

| Silicone Gasket | Silicone Rubber | -60 to 400 | 100 | High Temperature Applications |

| PTFE Gasket | Polytetrafluoroethylene | -450 to 500 | 150 | Chemical Resistant Applications |

| Viton Gasket | Fluoroelastomer | -40 to 400 | 250 | Aerospace and Automotive Industries |

When selecting the right propane tank rubber gasket, several key factors must be taken into account to ensure optimal performance and safety. First, the temperature resistance of the gasket material is crucial. According to industry reports, rubber gaskets must withstand temperature variations typically ranging from -40°F to 230°F (-40°C to 110°C). Choosing a gasket that can endure these conditions without degrading or losing integrity is vital for maintaining a secure seal that prevents leaks.

Another important aspect is the chemical compatibility of the rubber material with propane. Different types of rubber exhibit varying levels of resistance to hydrocarbons. Data from the American Society for Testing and Materials (ASTM) indicates that neoprene and fluorocarbon rubber show superior performance in environments involving propane, due to their resilience against chemical attack. Additionally, proper sizing of the gasket is essential; an ill-fitting gasket can lead to leaks and unsafe conditions. It's recommended to carefully measure the flange dimensions of the propane tank and ensure that the chosen gasket meets these specifications for effective sealing. By considering these factors, users can select a rubber gasket that not only meets their functional needs but also enhances the overall safety of their propane storage system.

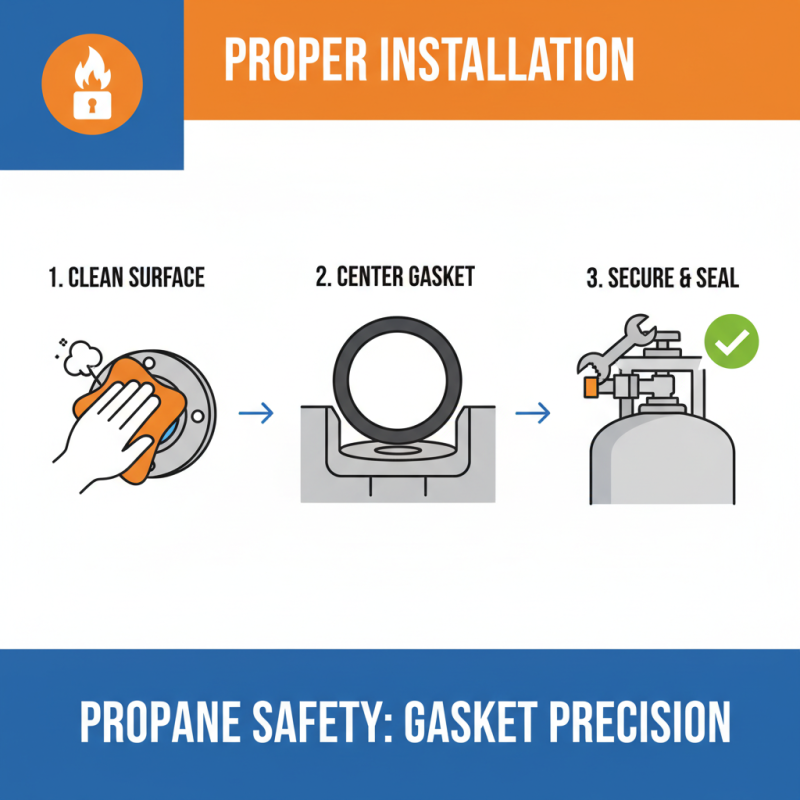

When it comes to properly installing a propane tank rubber gasket, precision and care are essential for ensuring safety and efficiency. Start by ensuring that the area around the tank is clean and free from any debris. A dirty or contaminated surface can compromise the effectiveness of the gasket and lead to leaks. Carefully place the rubber gasket onto the tank's flange, making sure it is centered and flat against the surface. A misaligned gasket can result in poor sealing, leading to potential hazards.

Tip: Before installation, inspect the gasket for any signs of wear or damage. A worn-out gasket won't provide a proper seal, which could create dangerous situations. It’s advisable to replace gaskets that show cracking, brittleness, or deformation.

Once the gasket is in place, secure it with the appropriate fittings. Tighten the fittings evenly and carefully to avoid over-torquing, which can damage the gasket and compromise the seal. After installation, it’s important to check for leaks using a solution of soapy water. Apply the solution to the gasket and surrounding areas; if bubbles form, you may need to redo the installation or replace the gasket. Regular maintenance checks will help ensure your propane system remains safe and efficient.

Tip: Always follow the manufacturer's guidelines for installation as they provide valuable information specific to your setup.

Maintaining the integrity of your propane tank's rubber gasket is crucial for ensuring safety and efficiency in your system. Regular inspection is one of the vital steps in proper maintenance. Check for any signs of wear and tear, such as cracks, hardening, or discoloration. These signs may indicate that it’s time for a replacement. Keeping the gasket clean from dirt and debris is also essential, as foreign materials can compromise its sealing ability and lead to potential leaks.

In addition to regular inspections, proper storage and handling of your propane tank and gasket can significantly extend their lifespan. Store tanks in a cool, dry place away from direct sunlight and extreme temperatures, which can deform the gasket over time. When fitting or removing the gasket, use gentle pressure to avoid overstretching or damaging it. Moreover, when in use, monitor the gasket’s performance periodically, especially during temperature fluctuations, as this can affect its elasticity. Taking these preventative measures will not only ensure a longer life for your rubber gasket but also contribute to a safer and more efficient propane system.