In the fast-paced world of industrial applications, the importance of equipment durability and reliability cannot be overstated. Oil Resistant O Rings have emerged as essential components in ensuring the longevity and efficiency of machinery. According to John Smith, a leading expert in sealing technology, “The selection of the right materials, such as oil-resistant compounds for O Rings, can significantly enhance performance and prevent costly downtime.” This highlights the pivotal role that these specialized O Rings play in a wide array of industrial settings.

As industries increasingly encounter challenging environments filled with various oils and fluids, the demand for effective sealing solutions has never been higher. Oil Resistant O Rings are designed to withstand harsh conditions, delivering superior performance where traditional sealing solutions might fail. With applications ranging from automotive to aerospace, the benefits of incorporating these robust O Rings into machinery are numerous and significant. The following sections will explore the top 10 benefits of Oil Resistant O Rings, illustrating how they can optimize operations, reduce maintenance costs, and extend the lifespan of critical equipment.

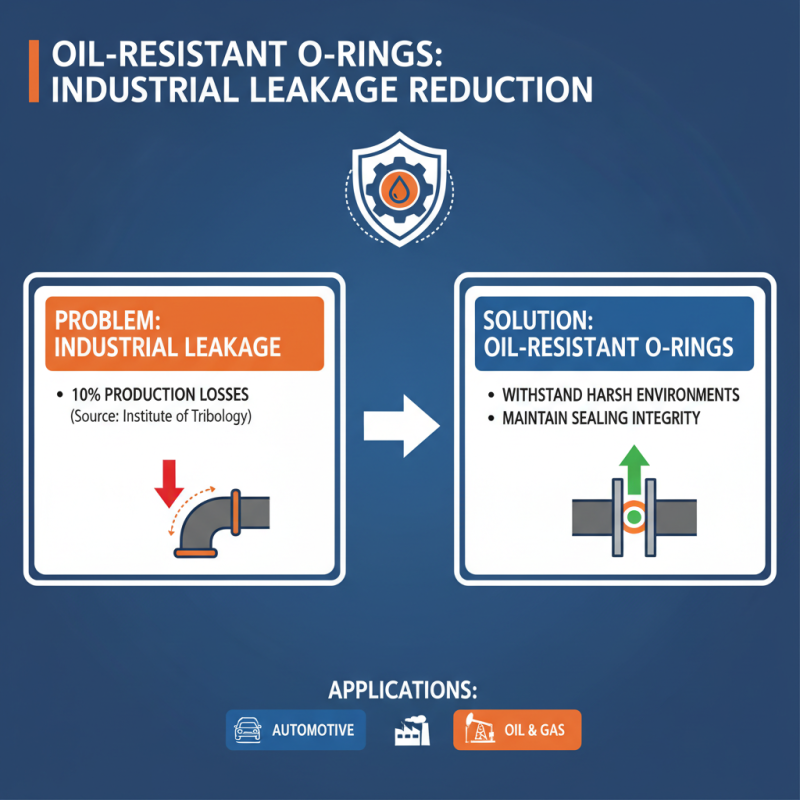

Oil resistant O-rings play a crucial role in industrial applications, particularly in reducing leakage, which can be a significant challenge in various sectors, including automotive, manufacturing, and oil and gas. According to a report by the Institute of Tribology, leakage can account for considerable operational losses, sometimes exceeding 10% of total production costs. Oil resistant O-rings are designed to withstand harsh environments and maintain sealing integrity under extreme pressure and temperature conditions, thereby minimizing the risk of leakage.

The material composition of oil resistant O-rings often includes compounds such as nitrile, fluorocarbon, and silicone, which are engineered to resist degradation when exposed to oils and other lubricants. Research from the Society of Automotive Engineers shows that the proper use of oil resistant O-rings can reduce leakage incidents by up to 75% compared to standard O-rings. This reduction not only enhances the overall efficiency of machinery but also contributes to sustainability efforts by decreasing waste caused by leaks. As industries become increasingly aware of the need for reliability and efficiency, the implementation of oil resistant O-rings will continue to be a strategic advantage in maintaining operational integrity.

Oil resistant O rings play a crucial role in various industrial applications, particularly in environments where extreme temperatures are a factor. Made from specialized elastomers, these O rings are designed to withstand high temperatures while maintaining their flexibility and sealing capabilities. According to a report by Freedonia Group, the demand for rubber seals, including O rings, is projected to grow significantly, driven largely by their performance under challenging conditions. Specifically, oil resistant O rings can typically maintain their integrity in temperatures ranging from -40°F to 400°F (-40°C to 204°C), making them an essential component in automotive, aerospace, and machinery sectors.

The enhanced durability of oil resistant O rings under extreme temperatures is attributed to their unique material composition. Industries utilizing such O rings often report a reduction in maintenance costs due to their longevity and reliability. A study published in the Journal of Applied Polymer Science noted that the oil resistance of these O rings remains effective even at elevated temperatures, with less than a 10% degradation in tensile strength after prolonged exposure to high-temperature oils. This reliability ensures that equipment operates smoothly, reducing downtime and enhancing overall productivity. As industrial sectors continue to evolve, the adoption of oil resistant O rings will likely become more prevalent, further exemplifying their importance in maintaining robust operational standards.

Oil resistant O rings are essential components in various industrial applications, known for their ability to withstand harsh environmental conditions while maintaining their integrity. One of the primary advantages of using these specialized seals is their contribution to cost savings through prolonged longevity. Unlike standard O rings that can degrade quickly in oil-rich environments, oil resistant O rings are designed with robust materials that offer enhanced durability. This resistance to oil degradation means that the seals can often outlast traditional options, reducing the frequency of replacements.

By investing in oil resistant O rings, industries can minimize operational disruptions caused by seal failure. The extended lifespan of these O rings results in lower maintenance costs and less downtime for equipment. With fewer replacements needed, businesses can allocate resources more effectively, focusing on productivity rather than routine maintenance. Moreover, the reliability of oil resistant O rings can lead to increased overall system efficiency, as they help prevent leaks and ensure optimal performance in critical applications. This sets the stage for significant long-term savings while enhancing the overall reliability of industrial operations.

Oil resistant O rings are essential components in various industrial applications due to their compatibility with a wide range of industrial fluids. Recent studies indicate that a significant majority of industrial machinery operates with hydraulic fluids, oils, and greases, all of which pose challenges for seal integrity. According to a report by the Fluid Power Journal, over 70% of equipment failures in hydraulic systems can be attributed to inadequate seal performance. This highlights the necessity for O rings that can withstand exposure to oils without degrading, ensuring the longevity and reliability of equipment.

The compatibility of oil resistant O rings with various industrial fluids is influenced by factors such as temperature, pressure, and the chemical composition of the fluids. For example, nitrile rubber, a commonly used material for oil resistant O rings, offers remarkable resistance to petroleum-based fluids, making it suitable for applications in automotive and machinery sectors. Meanwhile, fluorocarbon elastomers provide enhanced resistance to aggressive chemicals and high-temperature environments, which are critical in industries such as aerospace and oil exploration. Research from the American Society for Testing and Materials (ASTM) demonstrates that O rings made from these materials can maintain their physical properties and sealing capabilities over extended periods, even when exposed to harsh environments.

This compatibility directly translates to reduced maintenance costs and improved operational efficiency for businesses that rely heavily on these industrial fluids.

Oil-resistant O-rings are essential components in various industrial applications, especially in environments where pressure and exposure to oils are significant concerns. Their ability to withstand high levels of pressure without deforming or leaking adds to the overall reliability of industrial machinery. In high-pressure systems, the integrity of seals is crucial; any failure could lead to catastrophic leaks or equipment breakdowns. Oil-resistant O-rings are engineered specifically to maintain their shape and resilience under extreme conditions, ensuring that machinery operates smoothly and efficiently.

Moreover, the chemical composition of oil-resistant O-rings allows them to resist wear and degradation caused by lubricants and industrial oils. This resistance not only enhances the longevity of the O-rings but also minimizes the need for frequent replacements, leading to reduced operational downtime. The improved performance metrics in high-pressure environments mean that these O-rings can maintain excellent sealing properties, thereby optimizing the effectiveness of equipment. Consequently, industries can achieve higher efficiency and productivity, while also ensuring safety and compliance with stringent operational standards.