Gas Resistant O Rings play a crucial role in various industries due to their unique properties. Dr. Emily Carter, a leading expert in materials science, emphasizes, "The right O-ring can be the difference between success and failure in gas applications." These components provide excellent sealing capabilities in environments exposed to gases.

The uses of Gas Resistant O Rings span multiple applications. They are essential in the automotive, aerospace, and chemical processing sectors. Their ability to resist deterioration under extreme conditions is vital. However, not all O-rings are created equal. Manufacturers must carefully select materials based on specific gas interactions.

Despite their effectiveness, challenges remain. Some users underestimate the importance of regular inspections. Over time, O-rings can degrade, leading to potential failures. Awareness and proactive measures are key to ensuring reliability in gas-related applications. The journey toward optimal usage of Gas Resistant O Rings continues, filled with learning and growth potential.

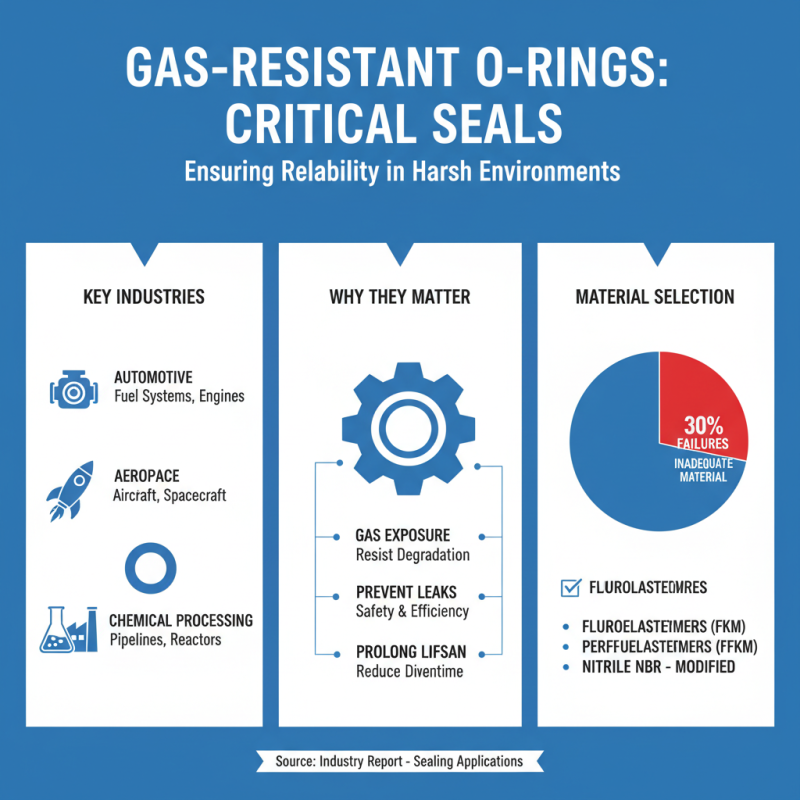

Gas-resistant O rings play a critical role in various industries. They are designed to withstand exposure to gases, making them essential in applications like automotive, aerospace, and chemical processing. According to a recent industry report, approximately 30% of failures in sealing applications can be traced back to inadequate material selection.

The significance of gas-resistant O rings lies in their ability to maintain integrity under pressure and temperature variations. Their specialized materials, such as fluorosilicone and FKM, provide unique properties that resist permeation. This is vital to ensuring safety and efficiency in systems where leaks could lead to catastrophic failures. In fact, tests show that gas permeation can be reduced by as much as 90% with the correct O ring materials.

However, not all gas-resistant O rings are created equal. Different gases interact distinctly with sealing materials. In some cases, users report unexpected performance issues, even with certified products. Continuous research is necessary to discover how materials age and respond to new gas compositions in real-world conditions. This area still requires much exploration, as customer feedback often reveals gaps in existing data and product performance over time.

Gas resistant O rings are essential in various industries. They provide effective sealing solutions for applications involving gases. These rings prevent leaks in systems that transport gas safely and efficiently.

In the automotive sector, gas resistant O rings are crucial. They are used in fuel systems, ensuring proper sealing of fuel injectors and pumps. This helps prevent fuel evaporation, which can lead to environmental harm. In the aerospace industry, these O rings are utilized in fuel tanks and engines. They withstand extreme temperatures and pressures, ensuring the safety and reliability of aircraft systems.

Additionally, the oil and gas sector relies heavily on gas resistant O rings. They are used in pipeline sealing and drilling equipment. These rings endure harsh conditions, including corrosive substances and high temperatures. However, not all O rings perform equally. Some may wear out faster than expected. This can lead to system failures, which companies must address proactively. Regular maintenance and inspections are key to ensuring reliability.

Gas resistant O rings are crucial in various sealing applications. They are designed to withstand exposure to different gases. This feature is vital in industries like automotive and aerospace. These O rings maintain their integrity under pressure. They also prevent gas leaks effectively.

One significant benefit is their durability. Gas resistant O rings often last longer. This extends the life of equipment and reduces maintenance costs. Their reliable performance can boost safety levels. Users can trust that gases won't escape or mix. This reliability is essential in high-stakes environments.

Choosing the right material is important. Not all O rings are created equal. Some may degrade faster under specific conditions. Regular testing and inspections help ensure effectiveness. Making informed choices can minimize risks. Reflecting on the material’s compatibility with gases is essential. Many overlook this aspect, leading to potential failures.

This bar chart illustrates the various applications of gas resistant O rings in 2026, showcasing the estimated units sold in different industries such as Automotive, Aerospace, Oil & Gas, Chemical Processing, and Medical Equipment. The data highlights the key sectors benefiting from the performance and reliability of gas resistant O rings in sealing solutions.

When selecting materials for gas-resistant O rings, understanding their properties is crucial. Different gases react variably with materials. For instance, fluorocarbon compounds are known for their excellent resistance to a wide range of gases. Data shows they withstand temperatures up to 200°C while maintaining structural integrity. However, they are not immune to all substances. Prolonged exposure to certain chemicals may lead to degradation.

Another viable option is silicone. It has a lower thermal stability compared to fluorocarbon but offers good resilience against oxidizing gases. Reports indicate that silicone O rings can maintain performance in environments with varying temperatures. Yet, users must be mindful. In certain applications, silicone may swell or change shape. This can compromise effectiveness.

The choice of material is a balancing act. Each option comes with benefits and limitations. Engineers must assess their unique conditions carefully. Understanding gas types and operating environments directly impacts O ring performance. Proper selection leads to enhanced reliability in applications involving gases. Having the right material can save on maintenance costs and prevent failures.

| Use Case | Material | Gas Type | Temperature Range (°C) | Benefits |

|---|---|---|---|---|

| Petrochemical Processing | FKM (Viton) | Natural Gas | -20 to 200 | Excellent thermal stability and high flexibility. |

| Automotive Fuel Systems | HNBR | Benzene | -30 to 150 | Excellent resistance to fuel, good compression set. |

| Chemical Processing | EPDM | Hydrogen Sulfide | -40 to 120 | Superior resistance to chemicals and weathering. |

| Oil and Gas Extraction | FFKM | Methane | -15 to 300 | Outstanding sealing capabilities in extreme environments. |

| Pharmaceutical Equipment | Silicone | Compressed Air | -60 to 200 | Non-toxic and suitable for cleanroom applications. |

Installation and maintenance of gas-resistant O rings can significantly enhance their performance. Proper installation begins with a clean surface. Even tiny debris can lead to leaks. A study shows that 30% of O ring failures result from improper installation. It’s vital to inspect the grooves and ensure they are free from contaminants.

When installing, avoid excessive stretching or twisting. Such practices can harm the O ring. According to industry reports, approximately 15% of failures occur due to inadequate handling. Using appropriate tools for seating the O ring ensures it stays in place. Moreover, a lubricant can aid in installation but should be compatible with the O ring material.

Routine maintenance is equally crucial. Regular inspections can uncover wear and tear. Early detection can prevent significant leaks and failures. It's worth noting that environmental factors also play a role. Temperature fluctuations can affect performance. If mismanaged, this could lead to increased operational costs. Keeping records of inspections can help identify patterns that may require attention.